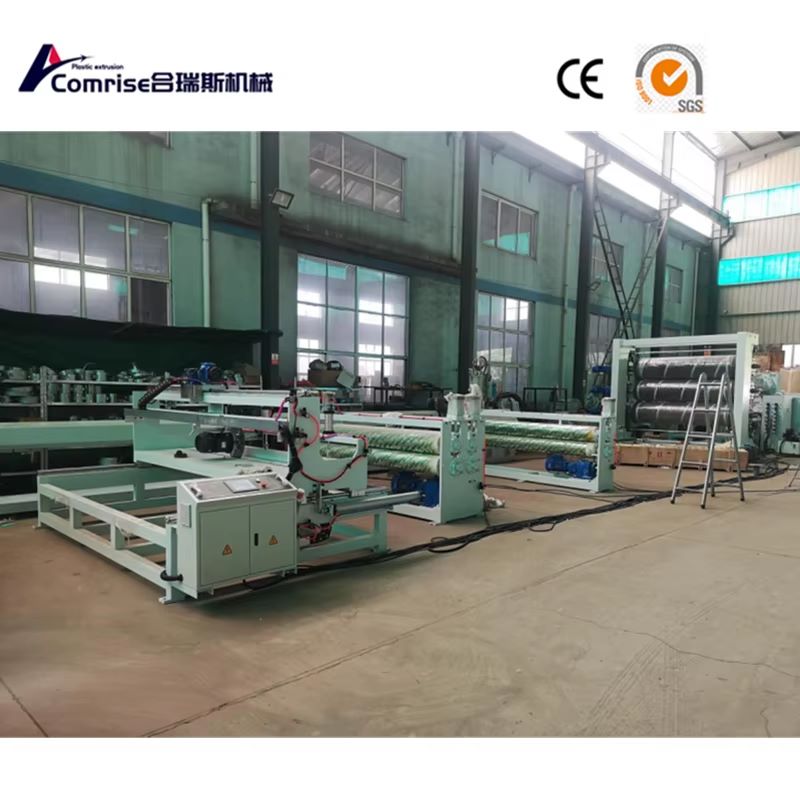

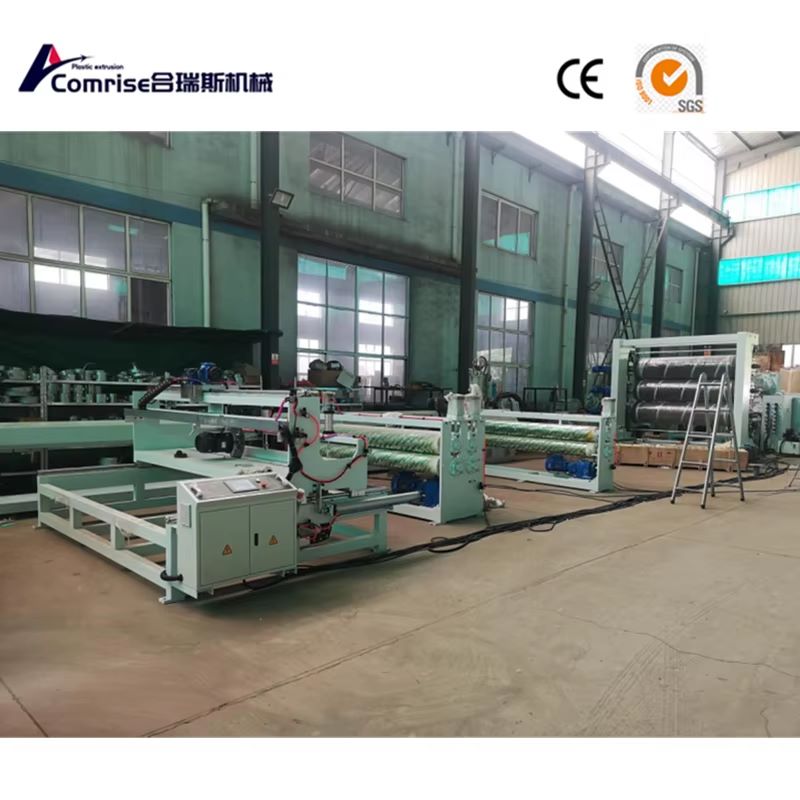

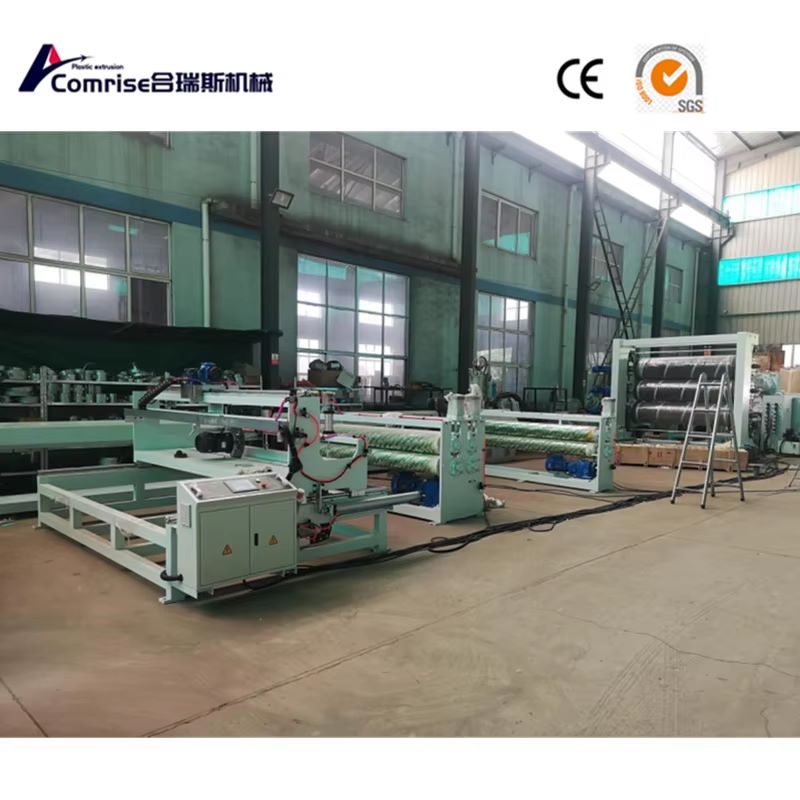

Densissima tabula extrusionem productio linea

Mitte Inquisitionem

Plastic densissima tabula machina

PP / PE / PVC densissima laminis habere characteres de lumine pondus, uniformis crassitudine, lenis superficies, bonum calor resistentia, alta mechanica vires, optimum et stabilitatem, bonum electrica velut inutulationem, et non toxicity. Late in egetContainers, electronic adjumenta, machinery, pharmaceuticals et aqua curatio, etc.

I. High facultatem, circa 400-550KG / H (ad SJ130 Una Screw)

II. Energy Saving: XX% magis industria-agentibus quam Ordinarius machinis sumus fabricare

III. Quod operatio plene in principiis ergonomicorum, quae potest facere munera magis completum et operationem simpler.

4. Equipped with mold temperature control, stainless steel pump body, precise temperature control from room temperature to 300 ℃, temperature accuracy within ± 1 ℃, fully temperature controlled, fast heating, good temperature maintenance, long service life, saving time

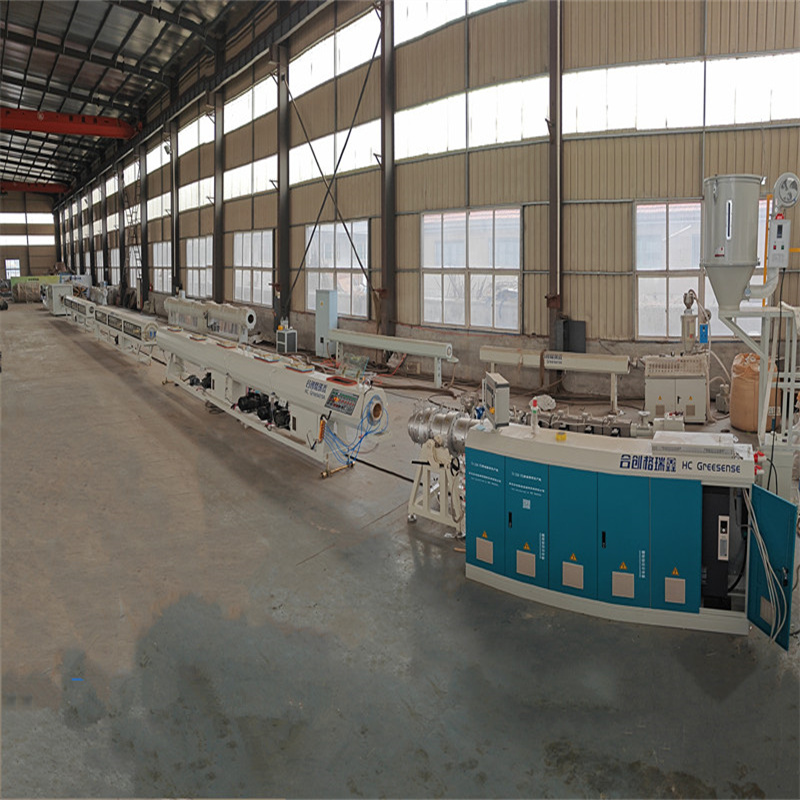

I. Et specialis screw consilio potest efficaciter amplio plasticization rate, cum productio facultatem ad DCCC kg / h.

II. Densissima tabula extrusionem productio linea optimized electrica consilio potest consequi praecise disparet et automatic control et fabricare machina et sumus Sina Top Factory et High Quality.

III. Productio linea adoptat Siemens Motors, ABB frequency Converters, Schneider Contactores, Siemens PLC control Systems, et Siemens tactus Screens. Certissima electrica components et specialiter disposito programs potest curare lenis apparatus operatio, nisi virtute et redigendum vastum.

|

CHRINGULA |

120-180mm |

|

L / d |

XXXIII: I |

|

Main Motor Power |

132-280kw |

|

Sheet Crassitudo |

3-30mm |

|

Sheet width |

1200-3000MM |

|

Output |

600-1000kg / h |

|

Installed potentia |

200-580kw |

Ut a Quotation autem