Productio linea HDpe Pipe HDPE

Mitte Inquisitionem

Secundum variis usibus plastic Pe Pipes, quod requiritur ut habent mechanica vires, æstus resistentia, frigus resistentia, diaphanum et alia in eodem tempore, et necessarium ad continue inducere novo plastic in eodem tempore, et necessarium est ut continue inducere novo plastic in eodem tempore, et necessarium est ad continue inducere novo plastic et non est ad reponere continue ones. Pe Pipes sunt paulatim developing a gravibus ad lucem et ex uno functioni ad multifunctional, et colat extruditur composita plastic tres-layer pe fistulas facti novum genus pipe materia. Due to the various properties and functions of co extruded tubes that can be designed according to needs, the performance advantages of component materials can be fully utilized by selecting appropriate matrix and steel bars, as well as appropriate composition ratios and arrangement distributions, in order to obtain comprehensive properties such as high specific strength, high specific modulus, corrosion resistance, high temperature resistance, superconductivity, etc. that are difficult to achieve with Una materiae ut metalla, Polymers, LATERAMEN, etc. Unde, quod paulatim facti progressionem trend de plastic Pe Pipes in futurum.

Commodum coactus

I. Melius uber perficientur: Double coactus coactus technology potest ex extrude et compositum duo diversas materiae simul, plene utilitas ad commoda duo diversis materiae ad amplio uber perficientur.

II. Simpler Productio Productio: comparari cum Traditional Single-Layer Extrusionem Technology, duplex-iacuit coactus technology habet simplicior et magis industria-efficiente productio processus.

IV. Resource Salvis: Double Layer coactus technology potest simpliciorem repono et processui diversarum generum materiae, reducendo in vastum rudis materiae.

In summary, duplex-layer coactus technology factus est core technology de modern plastic vestibulum et late in variis industrias. Cum autem continuam incrementum scientia et technology, quod est credendum quod duplex-iacuit coactus technology erit a latior progressionem spatium

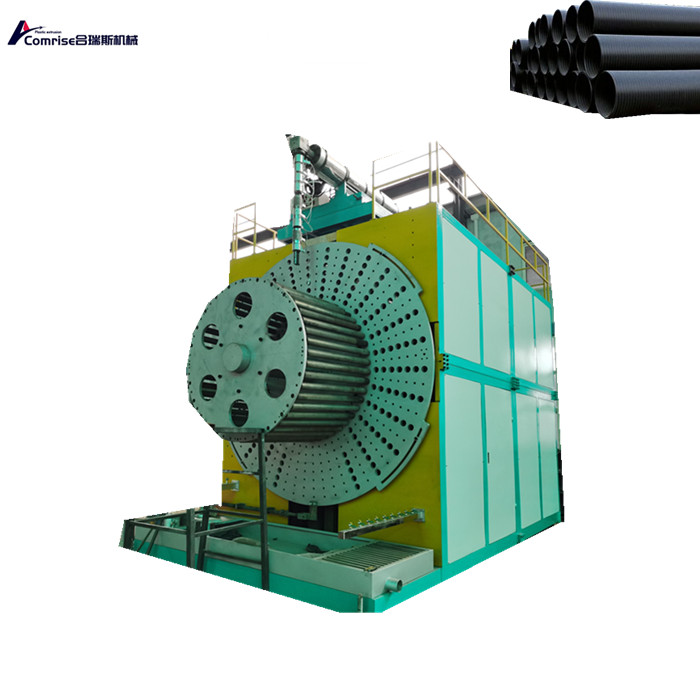

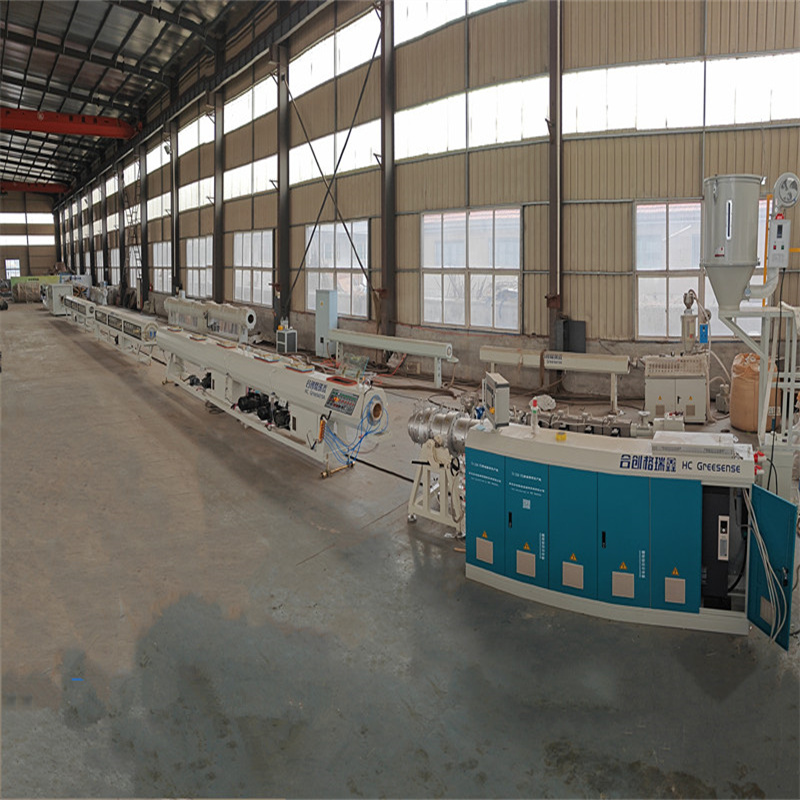

PE pipe extrusionem productio linea fluxus chart:

Productio linea HDpe Pipe HDpe Casio: Rudis Materials → → Vacuum PASTIVES → Hopper Dryer → Single Tank → Traction Culpa (Tank → Traction Culpa (Tank → Traction (Clothing Machina Machina)

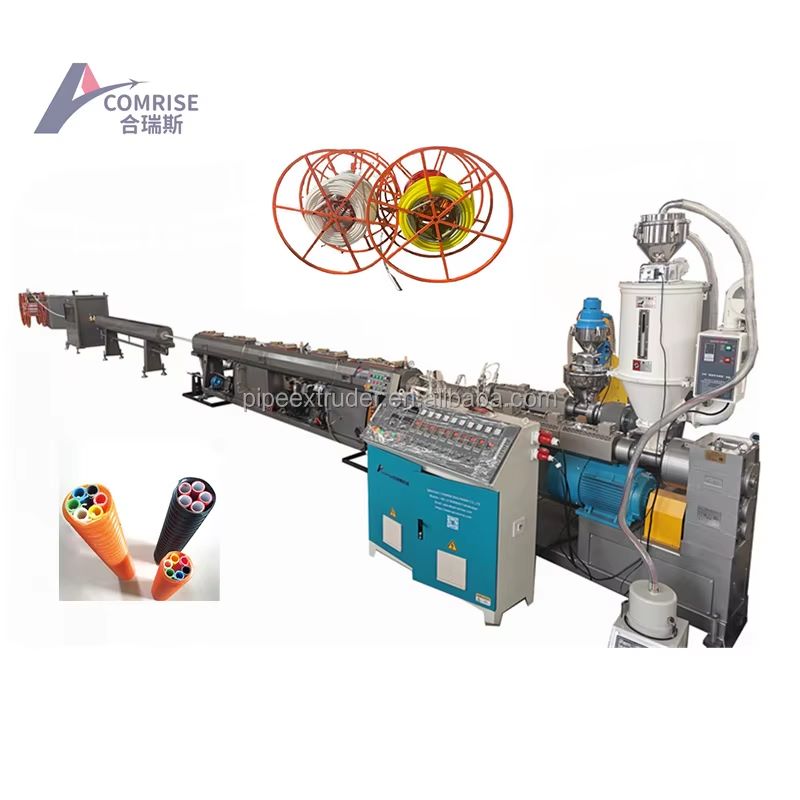

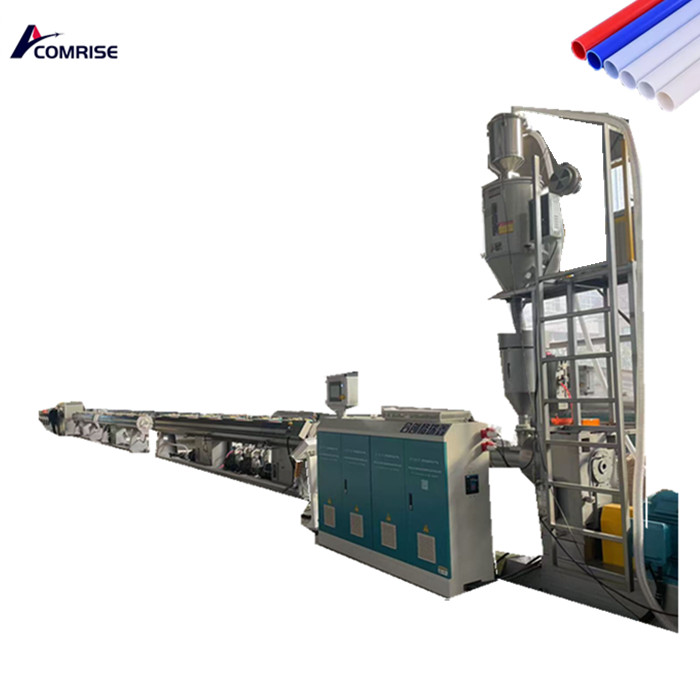

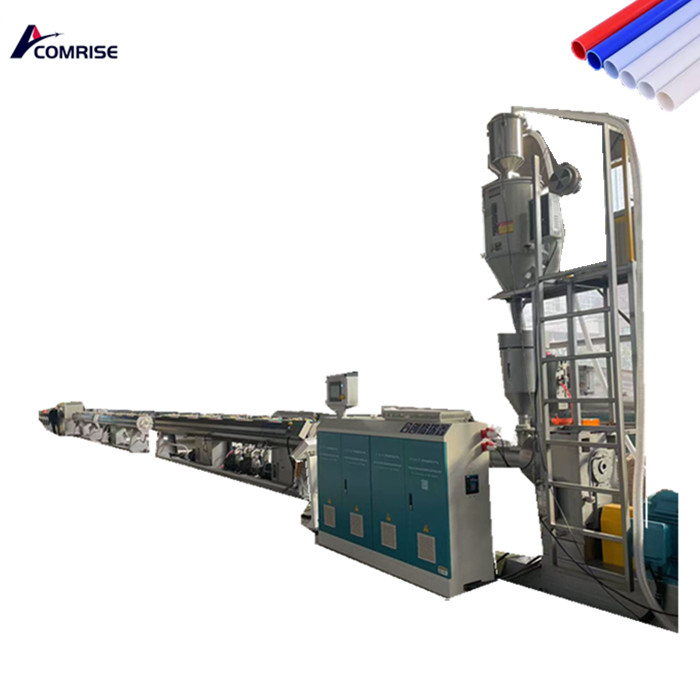

Application Description Polyethylene pipe extrusionem productio linea:

Haec extrusionem productio linea potest adhiberi pro productio pe fistularum diversis diametris, cum optimum rightitatis et flexibilitate, æstus resistentia, canus resistentia, excelsum mechanica vires, environmental accentus cracking resistentia, reptile deformatio resistentia, scelerisque nexu, et sic. Igitur hoc Pipeline productio linea est malle arbitrium pro Gas, aqua et agriculturae irrigationes pipeline systems inter urbana et rusticus areas.

Products Polyethylene Pipe extrusionem productio linea:

Capacity: Una stupra extruder, idoneam ad processui princeps-facultatem PE resinae cum maximam facultatem M kg / h. Diametro, de XVI ad DCCC mm. Adoptando rationabile consilio et absorbuit tutum productio technology, id est adeptus CE et ISO Certificat

COMMODO

Ut a Quotation autem