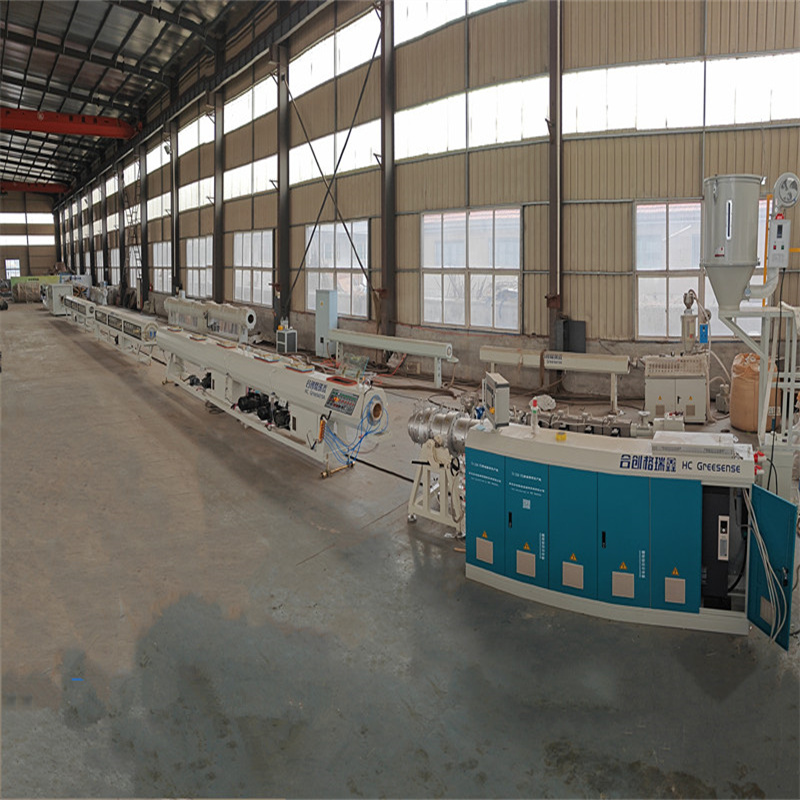

Et stillat irrigationes pipe productio linea est esse debugged

2025-05-12

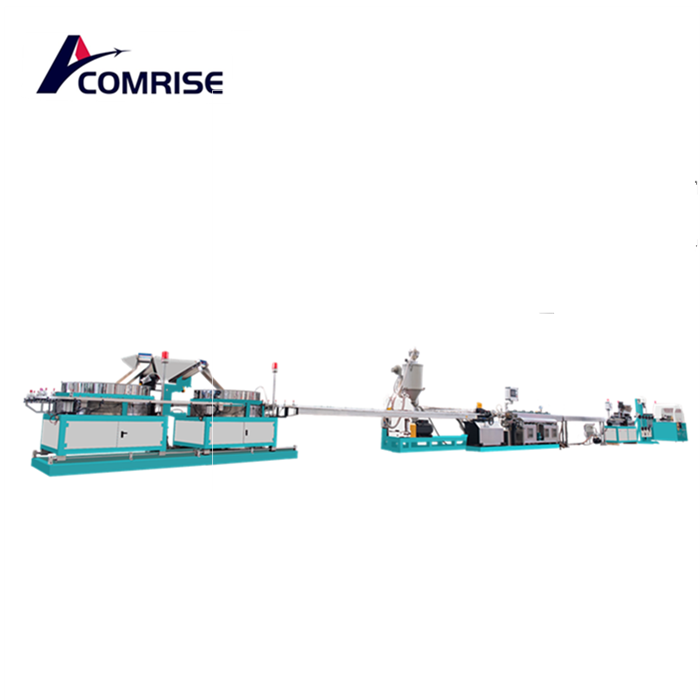

Composition of the crew

1. Flat dropper automatic recognition device

2. Flat dropper automatic feeding device

3. Extrusion device

4. Vacuum shaping device

5. Secondary cooling device

6. Rubber track tractor

7. Mechanical drilling and detection device

8. Dual station automatic winding machine

9. Microcomputer human-machine interface control

10. High power chiller units and constant water temperature devices such as water heating

11. Standard equipment includes a drip head alarm device, anti rotation tube device, semi-automatic screen changer, and pinhole hole detection device

This production line is a unit for producing inner embedded cylindrical drip irrigation pipes. It has the characteristics of beautiful appearance, high degree of automation, convenient operation, and high safety performance. Used for producing inner embedded cylindrical drip irrigation pipes. Internally embedded cylindrical drip irrigation pipes are widely used in many water-saving irrigation fields such as greenhouses, field planting, and greening projects.

The characteristics of the internally embedded cylindrical drip irrigation pipe are:

1. The spacing between droppers can be adjusted according to the needs of different crops, either equidistant or non equidistant.

2. The dropper adopts a unique design with a wide arc-shaped channel, full turbulence, self flushing, and strong anti blocking ability. The laying length is long, up to 100 meters.

3. It can be used both on plains and on hills and slopes.

4. A dropper with one or two water outlets or four water outlets has strong anti clogging ability.

5. The wall thickness can reach 1.2 millimeters, with a long service life.

Equipment features:

1. Controlled by a computer system and operated through a touch screen, the production process is stable, easy to operate, and energy-efficient.

2. Droplet feeding, screening and sorting, conveying and embedding, pipe discharge, punching, and winding are completed synchronously, with a high degree of automation.

3. The extruder screw and barrel are made of high-quality 38CrMoAlA nitride alloy, which has undergone ion nitriding treatment to achieve a surface hardness of HV850-1000. The screw has been optimized to achieve uniform plasticization of the extruded material and smooth surface of the pipe.

4. The extrusion mold and shaping cooling device have a unique structure, made of special materials, and have accurate sizing dimensions.

5. The tractor adopts variable frequency speed regulation, which can meet various process speed requirements. The track surface has a rubber protective layer, effectively preventing the drip irrigation pipe from being deformed by the tractor clamp.

6. The punching machine is a mechanical punching machine with fast punching speed and stable operation.

7. Adopting a duplex position coiler, the winding length can be adjusted as needed.